To ensure the efficiency of diesel engine piston rings, several measurements and tests are performed, the most important of which are:

Pin Ring Clearance Measurement:

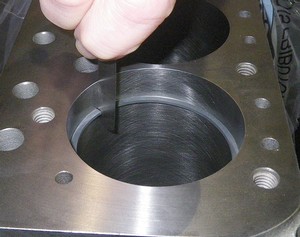

1. Side Clearance: The clearance between the piston ring and the piston ring groove in the piston must be measured to ensure the ring's freedom of movement, allowing it to remain in constant contact with the cylinder wall.

2. End Gap: The distance between the two ends of the piston ring when it is inside the cylinder. Appropriate measurements for this clearance vary depending on the engine type, and are usually between 0.20 and 0.30 (for example, 0.20 mm or 0.30 mm). Refer to the engine's maintenance manual to determine the correct measurement.

Pin Ring Tests:

1. Engine Compression Test: This test is an effective way to check the condition of the piston ring. The compression of each cylinder inside the engine is measured, and the readings must be within the manufacturer's specifications. If there is a significant decrease in compression (more than approximately 20% of normal compression) in a particular cylinder, this may indicate a piston problem.

2. Leak-down Test: This test helps pinpoint the exact location of the leak within the combustion chamber. If the leak is occurring from the oil cap or dipstick opening, the problem lies with the pistons or seals. This test is performed with the engine at normal operating temperature, the piston raised to the top position (TDC), and the valve closed.

3. Check Oil Consumption and Exhaust Smoke: Increased oil consumption or the appearance of blue or gray smoke from the exhaust are symptoms of piston damage and indicate that oil is leaking into the combustion chamber due to improperly tightened pistons.

4. Visual Inspection: The pistons and seals are inspected periodically, especially when the engine is disassembled, to ensure there are no cracks or damage.

These measurements and tests help assess the condition of the pistons and determine whether they are operating efficiently to maintain engine performance.