Fuel filters are among the most essential components in diesel injection systems. Their primary role is to protect the injection pump and injectors from contaminants that can cause severe damage or reduce combustion efficiency. Clean fuel is critical for the proper performance of the diesel pump, making the filter the primary protection line for the entire system.

Function of the Fuel Filter

1. Remove impurities such as dust, rust, and particles.

2. Separate water from diesel to prevent corrosion inside the pump and injectors.

3. Maintain stable fuel pressure inside the injection system.

4. Prevent injector nozzle clogging to ensure proper combustion.

Types of Diesel Fuel Filters

1) Primary Filter (Pre-Filter)

Installed before the lift pump.

Removes large particles and water.

Protects the pump from early wear.

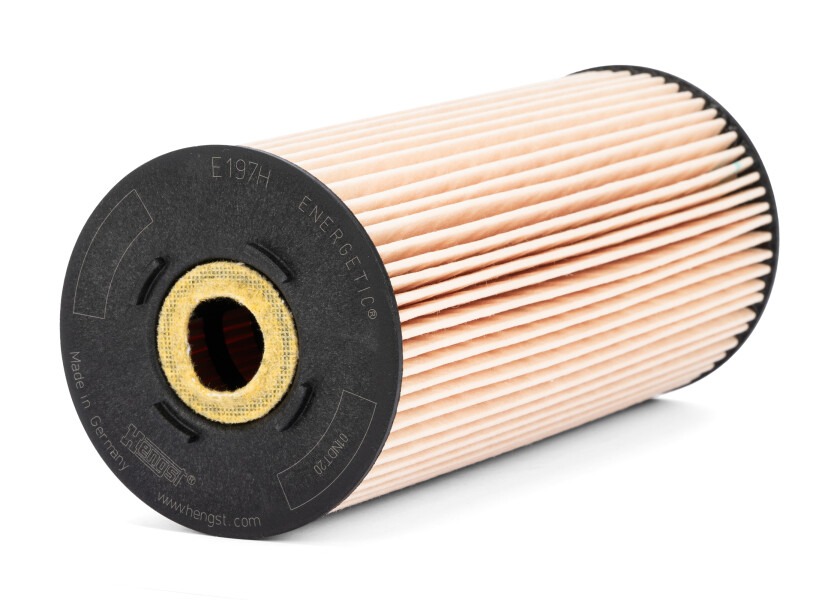

2) Secondary Filter (Fine Fuel Filter)

Located between the injection pump and injectors.

High-precision filtration down to a few microns.

Protects injector holes from clogging.

3) Water Separator Filter

Includes a chamber to collect water at the bottom.

May include a sensor for water level alerts.

Importance of Fuel Filters

- Reduces wear inside the injection pump.

- Prevents damage to plungers and barrels.

- Maintains stable fuel pressure and improves performance.

- Reduces fuel consumption and emissions.